Transform your manufacturing processes with S/4HANA for Manufacturing

built-in capabilities necessary to automate processes and support informed decision-making through AI, simulations, and real-time insights.

Research has proven that 86% of manufacturing businesses acknowledge that digital transformation is vital to their growth and staying competitive. Many of them are still dealing with legacy systems and processes that deliver limited visibility and are increasingly costly to maintain. As a result business line leaders and managers are forced to put innovation projects on the hold and focus their time and effort on problem-solving activities.

How can manufacturers overcome these challenges and accelerate their digital transformation?

The Solution: S/4HANA for Manufacturing.

S/4HANA provides a robust solution for manufacturers to streamline workflows across all manufacturing processes—from back-office functions through development, production, inventory management, distribution and more. With multiple deployment options on the private and public cloud, manufacturers can implement a highly robust and scalable solution to support manufacturing automation and drive operational and enterprise-wide analytics.

This solution enables performance, productivity and efficiency for manufacturers, improve production planning, supports complex assembly processes, accelerate operations, support seamless manufacturing engineering, enhance quality management, and more.

Why use S/4HANA to digitize your Manufacturing and Production processes?

SAP’s modern ERP is built on decades of SAP’s leadership in manufacturing—and has been specifically designed to serve as a company’s digital core, enabling seamless integration of data, systems and business processes that benefit from the scale, agility and flexibly of the cloud.

> Define flexible setups for product innovation and production with the required degree of complexity

> Plan production holistically – from high-level forecasting to production scheduling

> Run production operations with the most suitable approach in real time

> Embed quality management smoothly into production processes to help ensure the delivery of high-quality products

Production engineering

Rapid design, setup, and adjustment of your production flow help create efficient and agile manufacturing operations.

Product and production definition

Establish essential structures – such as bills of materials (BOMs), routings, and work centres – to run production successfully.

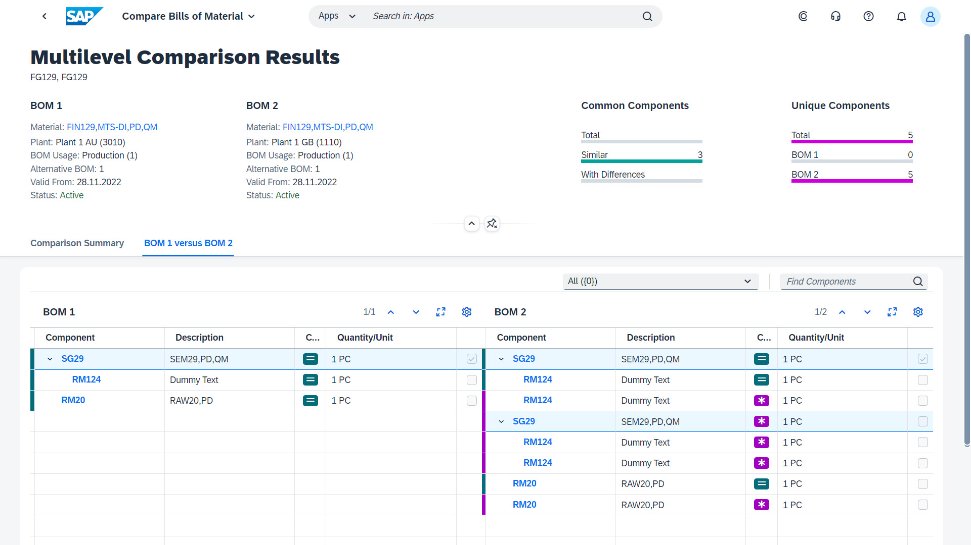

BOMs management

Manage and compare BOMs to facilitate structured processes for product changes.

Product configuration

Simplify and integrate product configuration based on models with the complexity that customers expect.

Establish essential structures – such as bills of materials (BOMs), routings, and work centres – to run production successfully.

BOMs management

Manage and compare BOMs to facilitate structured processes for product changes.

Product configuration

Simplify and integrate product configuration based on models with the complexity that customers expect.

Production planning

Intelligence based on real-time data and embedded AI paves the way to production optimisation.

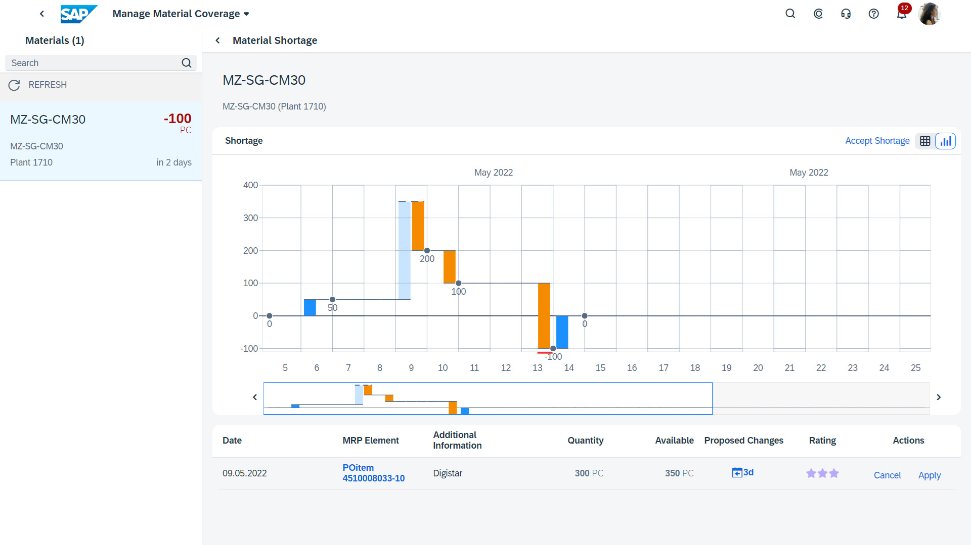

Demand forecasting optimisation

Simulate demand forecasts while considering supplier and capacity constraints for flexible optimisation.

Supply and demand matching

Help ensure materials are automatically ordered and available on time to manufacture products according to plan.

Optimal capacity utilisation

Monitor work-centre capacity to prioritize orders effectively and maximise the value of your resources and assets.

Simulate demand forecasts while considering supplier and capacity constraints for flexible optimisation.

Supply and demand matching

Help ensure materials are automatically ordered and available on time to manufacture products according to plan.

Optimal capacity utilisation

Monitor work-centre capacity to prioritize orders effectively and maximise the value of your resources and assets.

Warehouse management

Using a blend of real-time data, intelligent scenario planning, and mobile capabilities enables you to optimise stock levels with full transparency.

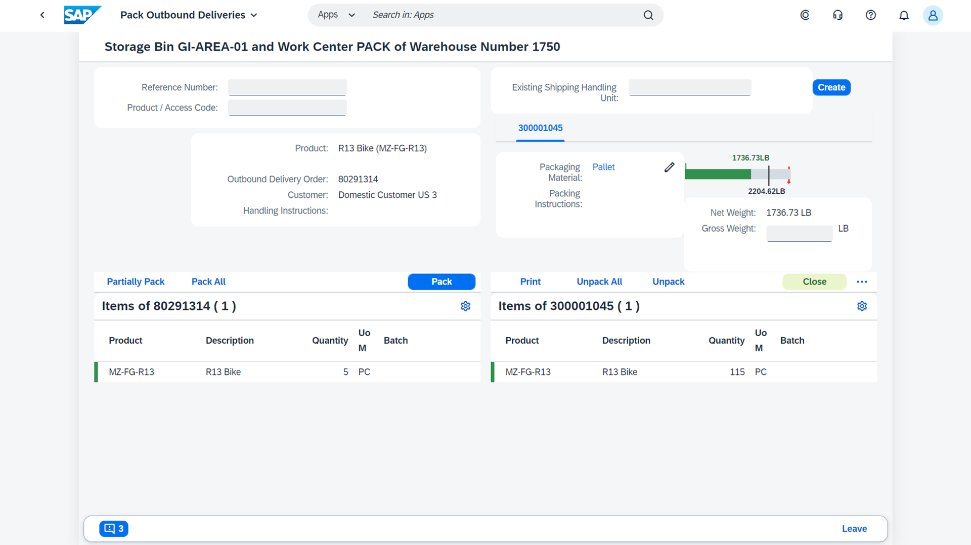

Warehouse optimisation

Run inbound, outbound, and internal warehouse processes with greater efficiency by using the wave management functionality.

Built-in warehousing capabilities

Benefit from warehouse management capabilities embedded in cloud ERP and integrated with

logistics processes.

Mobile enablement

Leverage a predefined mobile framework to run critical warehouse transactions on mobile devices.

Run inbound, outbound, and internal warehouse processes with greater efficiency by using the wave management functionality.

Built-in warehousing capabilities

Benefit from warehouse management capabilities embedded in cloud ERP and integrated with

logistics processes.

Mobile enablement

Leverage a predefined mobile framework to run critical warehouse transactions on mobile devices.

Manufacturing operations

Production control begins with comprehensive process transparency.

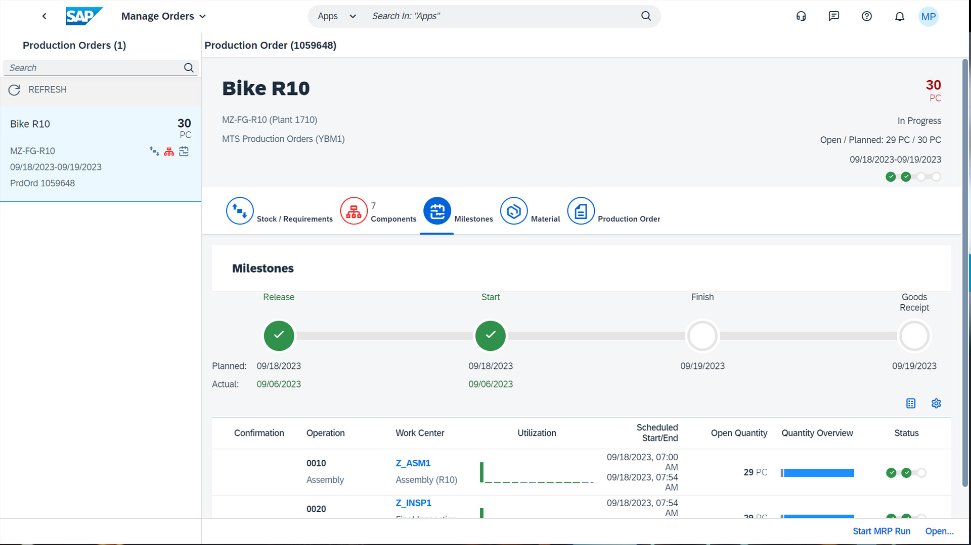

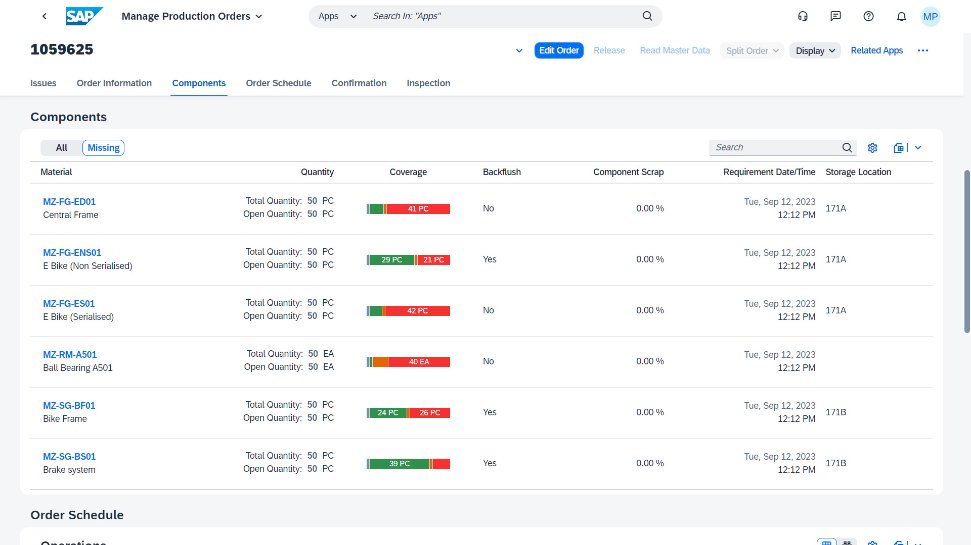

Order management

Create, edit, and manage production orders before releasing them to initiate production execution.

Real-time production updates

Maintain control over production progress and costs by receiving real-time updates from the shop floor.

Production monitoring

Use real-time insights and proactive notifications to detect and address issues before they impact manufacturing operations.

Create, edit, and manage production orders before releasing them to initiate production execution.

Real-time production updates

Maintain control over production progress and costs by receiving real-time updates from the shop floor.

Production monitoring

Use real-time insights and proactive notifications to detect and address issues before they impact manufacturing operations.

Manufacturing options

Process automation is supported across a broad range of manufacturing processes.

Discrete manufacturing management

Run discrete manufacturing processes across common setups, from make to stock and engineer to order.

Process manufacturing management

Coordinate process manufacturing processes based on process orders and master recipes.

Process enrichment

Apply additional processes, such as repetitive manufacturing, and Kanban, just-in-time, or just-in-supply replenishment.

Run discrete manufacturing processes across common setups, from make to stock and engineer to order.

Process manufacturing management

Coordinate process manufacturing processes based on process orders and master recipes.

Process enrichment

Apply additional processes, such as repetitive manufacturing, and Kanban, just-in-time, or just-in-supply replenishment.

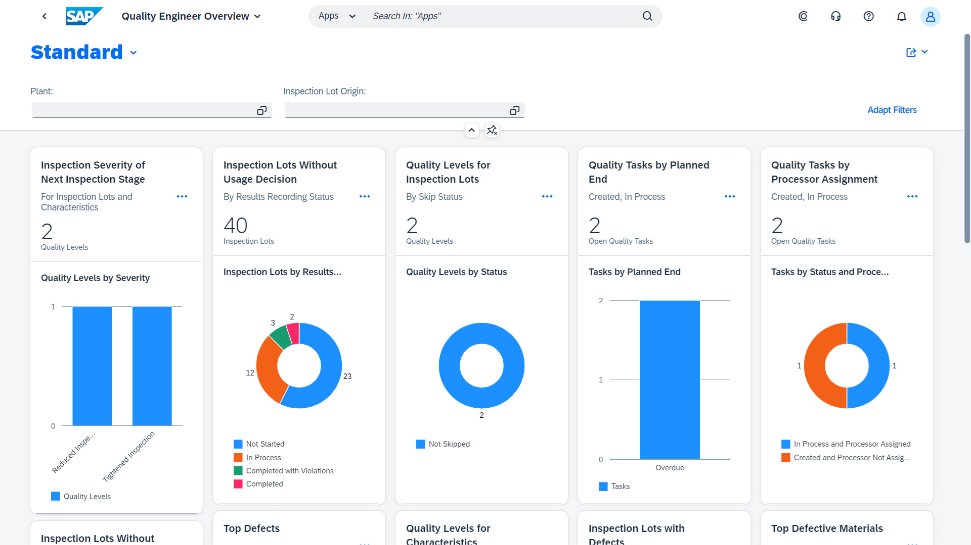

Quality management

Leveraging a cloud ERP with embedded quality management capabilities helps ensure your business delivers high-quality products.

Development and implementation of quality measures

Define holistically where and how to implement quality measures along the value-creation process.

Inspections and capture of results

Inspect materials against defined criteria and document them before using the data to decide on usage.

Product and process improvement

Analyse captured data to identify suitable follow-up actions, such as triggering an improvement process.

Define holistically where and how to implement quality measures along the value-creation process.

Inspections and capture of results

Inspect materials against defined criteria and document them before using the data to decide on usage.

Product and process improvement

Analyse captured data to identify suitable follow-up actions, such as triggering an improvement process.

en

en  de

de